Design flow for steel structures

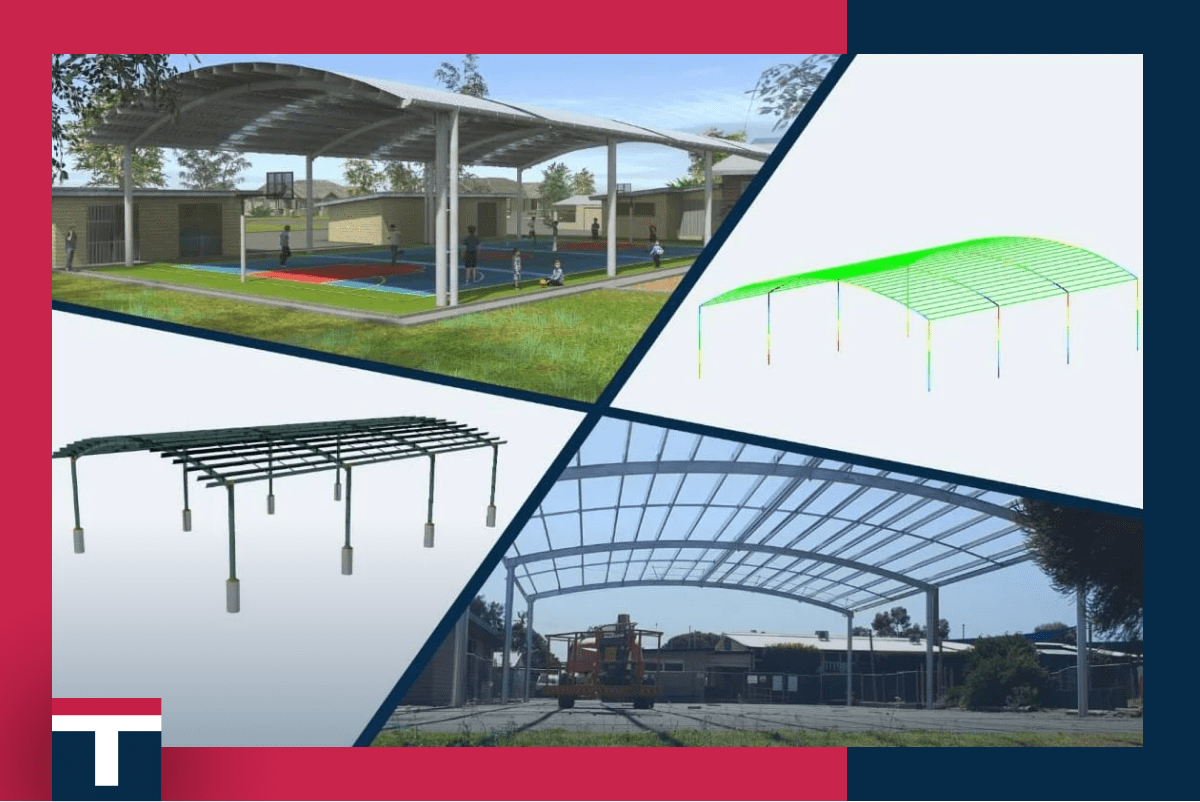

All structures have to pass through three main phases during their design – architecture, engineering and construction. These three design phases form a process also known by the acronym formed from the initial letters of these three phases – AEC. We are about to explain how steel structure passes through these phases and the benefits of hiring a single company like TIM Global Engineering for performing the entire design process.

First of all, in the planning phase, an architect performs conceptual design in liaison with the client to meet their demands and site location requirements. Architectural design contains instructions about the size and dimensions of the structure, its look and appearance, the layout of openings, walls and partitions and many more details required both for the client’s approval and for further stages of the design. All the data is given in the form of drawings, images, preliminary quantities or reference models originating from an architectural 3D model.

Engineering comes next. Based on the architectural design, structural engineers perform calculations, mostly by using FEA methods. The aim of this stage is to check the structure’s safety and it’s ability to withstand all the loads and forces acting on it, such as wind, snow or earthquake. This is done by choosing adequate material properties, cross sections, boundary conditions and structural system. In other words, it is the structural engineer’s responsibility to determine the most cost-effective solution for the given architectural layout, by respecting all the design rules given, in most cases, in structural codes like Eurocode, AISC, AS4100 and many others. Every single element in the structure must pass all the structural checks to be considered as reliable and safe for installation.

This is followed by the construction phase. In order to begin construction, we need fabrication and installation drawings. This means it is time for steel detailing to come to the scene. However, haven’t we forgotten something? Someone might say: “And what about connection design?” Connection design is part of the design that somehow always comes between structural calculations and steel detailing. Some engineers claim that steel detailers are responsible for the connection design part and that it is the engineer’s obligation just to provide internal forces obtained from their calculations. On the other hand, there are steel detailers with the opposite opinion – they expect that connections are designed by the engineer. So what is the right solution? The truth is somewhere in between. Connection design is an engineering problem, but it requires proper detailing. Connections should be detailed according to joint types in an analytical model – pinned, semi-rigid or rigid – and it should be calculated for all relevant load cases and combinations. Hence, there must be a proper balance between connection design and steel detailing, which leads to the conclusion that these two should be performed simultaneously in order to achieve optimal results.

Furthermore, the steel detailing stage requires highest precision, as all elements will be ordered, fabricated and installed based on information obtained from our 3D model. This information comes in the form of NC files, fabrication drawings, installation drawings, 3D models and bills of materials. Proper and accurate detailing prevents any omission that could cause prolongation in the construction time or bring about additional costs for the fabricators and contractors, and in this way, all elements will be easily transported and erected on site.

Even if the structure was constructed from steel elements only, we cannot avoid the usage of reinforced concrete. Certainly, in the above case, the foundations would be built from concrete, but there are many other situations where reinforced concrete could be found alongside steel elements, mostly in the form of composite structures, but also in other combinations. So as steel detailing is required for the fabrication and erection of steel elements, so is reinforced concrete detailing needed for a precise production and installation of reinforcement and for calculating bills of materials.

As you may see, the architectural, engineering and construction phases are interconnected and most important factors for their proper handling are good communication and information flow between teams. As we can cover all of the design processes within our office, you can be sure that this aspect is satisfied. Nonetheless, thanks to BIM (Building Information Modelling) tools, we can execute any of these tasks separately with cooperation with other teams – for instance, we are able to conduct structural design and detailing based on the architectural design of some other design office or to perform connection design based on the structural design provided by some other team and so on.

This was just a short description of steel structures design. Surely, much more could be written about each of the design phases, but we will leave this for some further posts where we can give more detailed explanations based on real-life examples and projects we have done for clients all around the world – the United Kingdom, Australia, New Zealand, Austria, Singapore, the UAE, etc.

Thank you for your interest in this topic. If you like this post, follow us for more interesting and exciting stories from TIM Global’s engineering world.